Widely used for the industrial welding market,such as metal equipment, stainless steel homeand other industries complex irregular welding process.

Description

Features

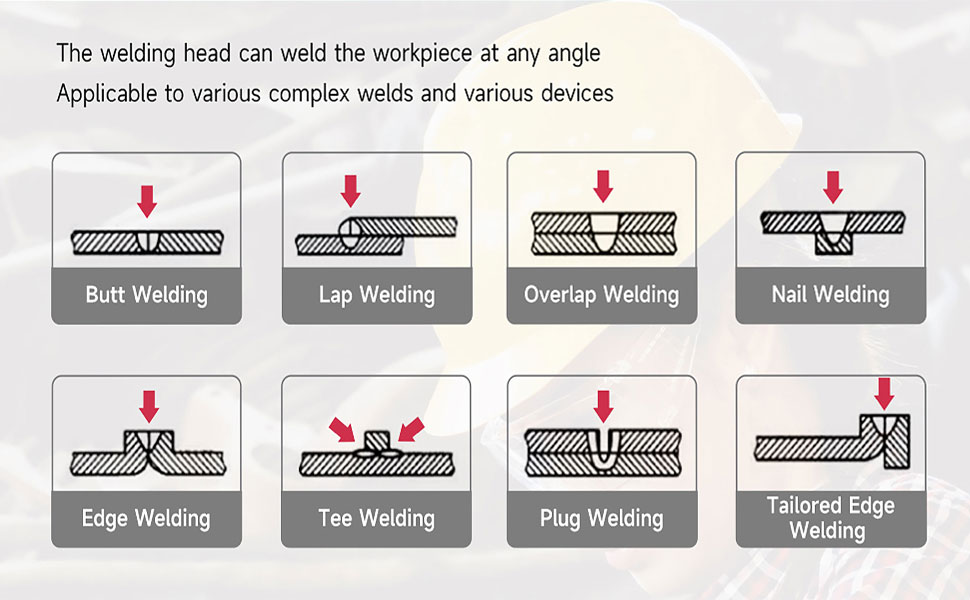

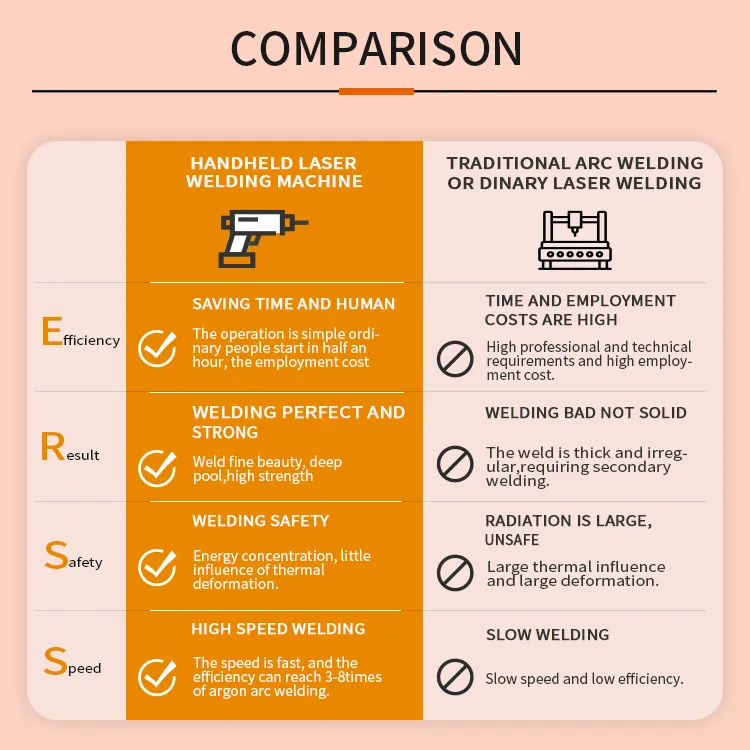

1.Portable and flexible, easy and simple operation, meet the welding of multiple angles and positions;

2.Equipped with 5m/10m imported optical fiber, flexible and convenient for outdoor welding;

3.Infrared positioning is used to verify the welding head position and verify the position during welding. The welding position is more accurate to ensure a more beautiful weld;

4.Not easy to deform, easy to polish. Solved the problems of welding penetration, welding nugget, welding quality and other problems that occurred when using argon arc welding;

5.The laser welding depth is large and the welding seam is firm. It is suitable for spot welding of various complicated welding seams and various devices.

Machine Parameters

Laser Power | IT-HW1000 | IT-HW1500 | IT-HW2000 | IT-HW3000 |

Laser source | Raycus/MAX/IPG | |||

Welding Thickness(SS) | 3mm | 4mm | 5mm | 7mm |

Welding Thickness(CS) | 3mm | 4mm | 5mm | 6mm |

Welding Thickness(AL) | 2mm | 3mm | 4mm | 6mm |

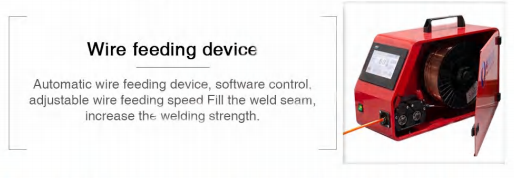

Feeding Wires' Dimension | 0.8-1.2mm | 0.8-1.6mm | 0.8-1.6mm | 0.8-2.0mm |

Output Fiber Length | 5/10/15m (Optional) | |||

Laser Wavelength | 1070±5nm | |||

Power Requirements | 220v±10%, 50/60HZ,1P | Raycus is 380V/3P and Max can be 380V/3P or 220V/1P, 50HZ/60HZ | 380v±10%, 50/60HZ,3P | |

Welding Speed | 0-120mm/s | 0-120mm/s | 0-150mm/s | 0-160mm/s |

Gross Power | 10KW | 12KW | 15KW | 20KW |

Air Humidity | 10-90% | |||

Laser Frenquency | 50-5000HZ | |||

Position System | Red Light Indicator | |||

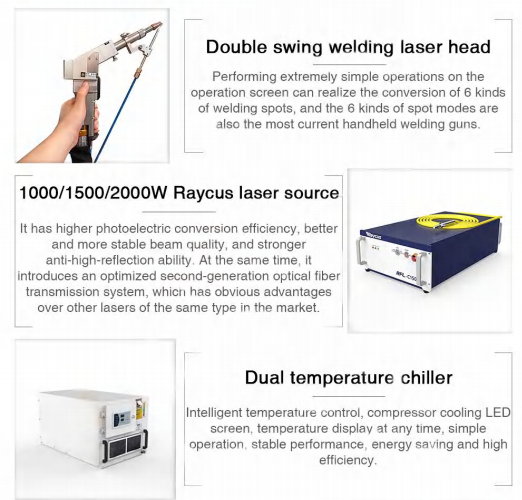

Welding Head | Wobble Laser Welding Head | |||

Power Adjustment | 10-100% | |||

Cooling Method | Water Chiller | |||

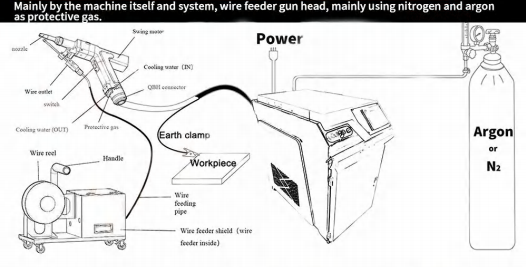

Shielding Gas Flow | 15-20L/min(Ar or N2) | |||

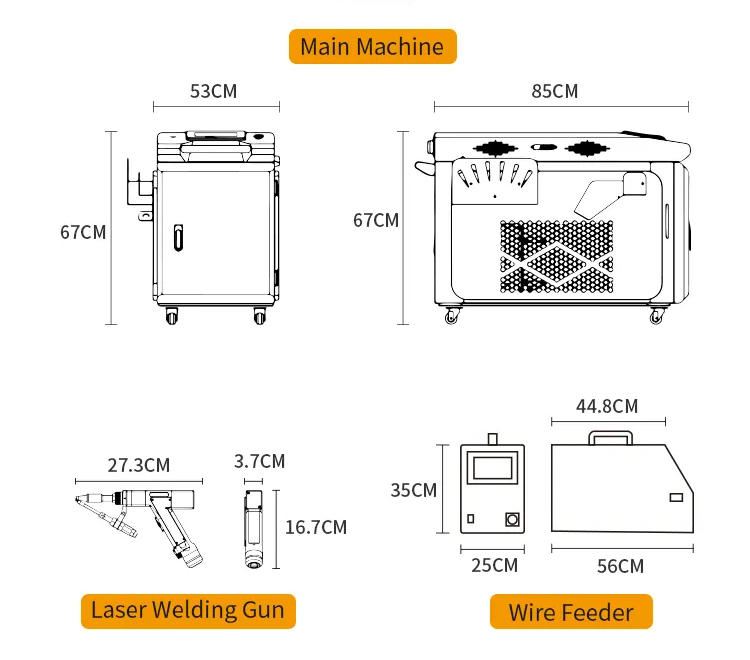

Machine Size | 450X1000X680mm | |||

Weight | 100 KG | |||

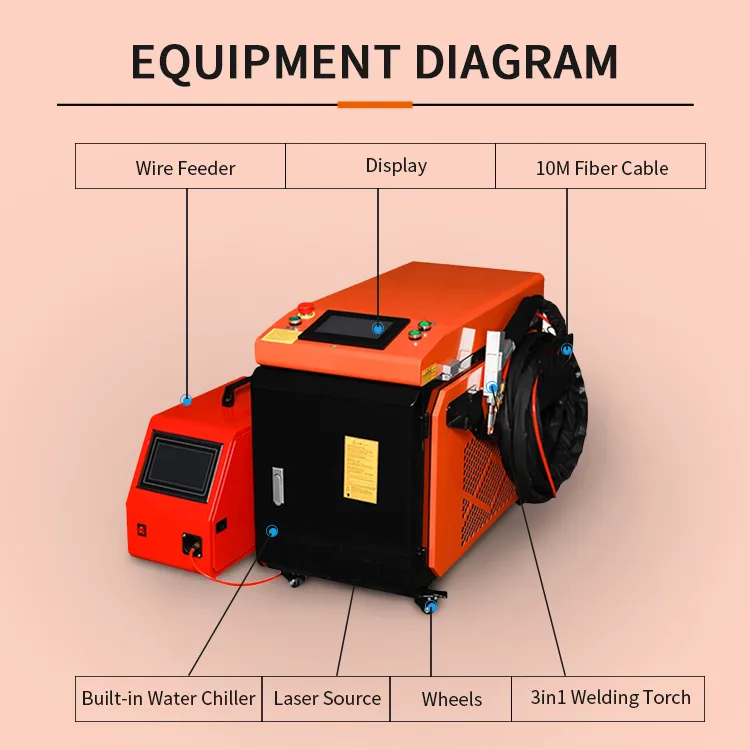

Machine Details

Machine Size

How Machine Works

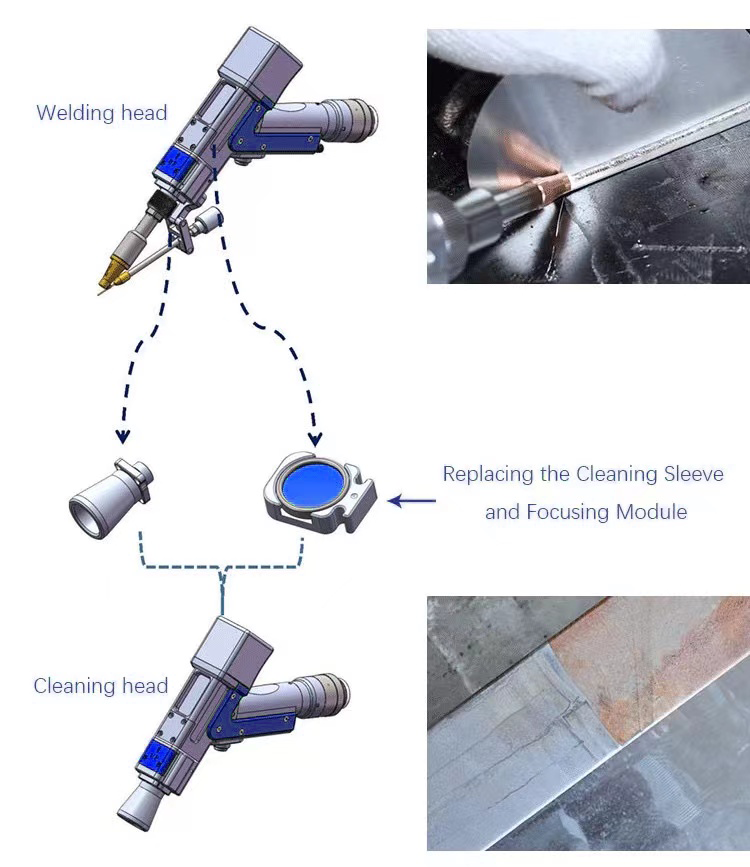

Optional Function:

After-sales Service

1) Free Pre-Sales Consulting / Free Sample Making

2) Strict Quality Control of Production

3) 3-5 Working Days Quick Delivery for Standard Machine

4) 1 Year Quality Guarantee

5) 24 hours Quick Feedback & After-Sales Service

6) Quick Back-up Parts Available & Technical Assistance

7) Free Online Training Service

8) Special Designing, Customized, OEM Order is accepted

Applicable Industries & Materials

Widely used in precision machining of small parts,rings,pendants,bracelets,dentures,mobile phone chargerinterfaces, hardware, watches, sporting goods, golf heads, medical equipment.Titanium alloy jewelry,especially used for holr patching of gold and silver jewelry,spot welding seam pattern,inlaid parts and other welding.

Suitable for welding stainless steel, carbon steel, alloy steel, spring steel, copper plate, aluminum plate, gold, silver, titanium ect.,

Welding Methods

Advantages

Certificates

Samples

Packages & Delivery

|

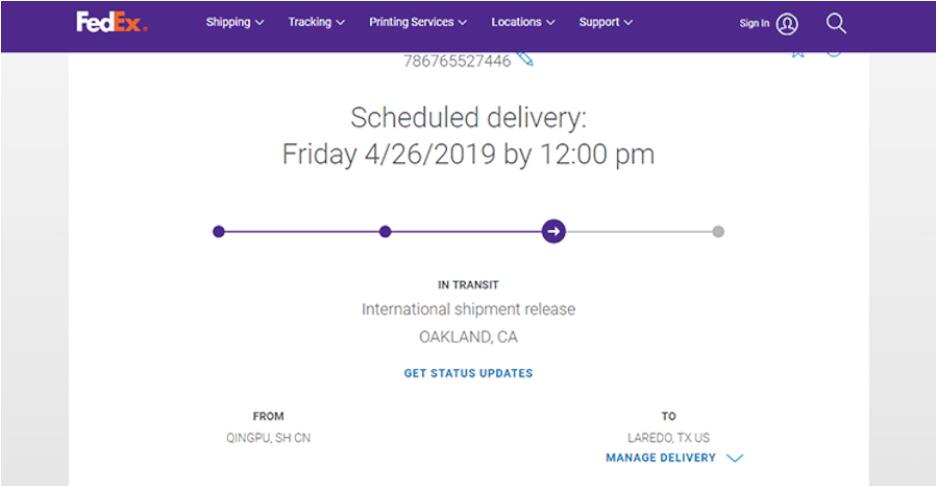

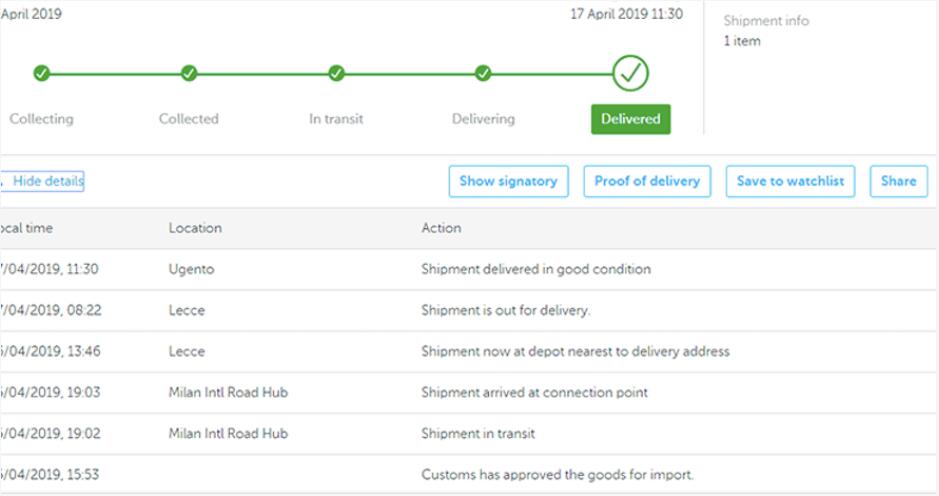

Transport Tracking

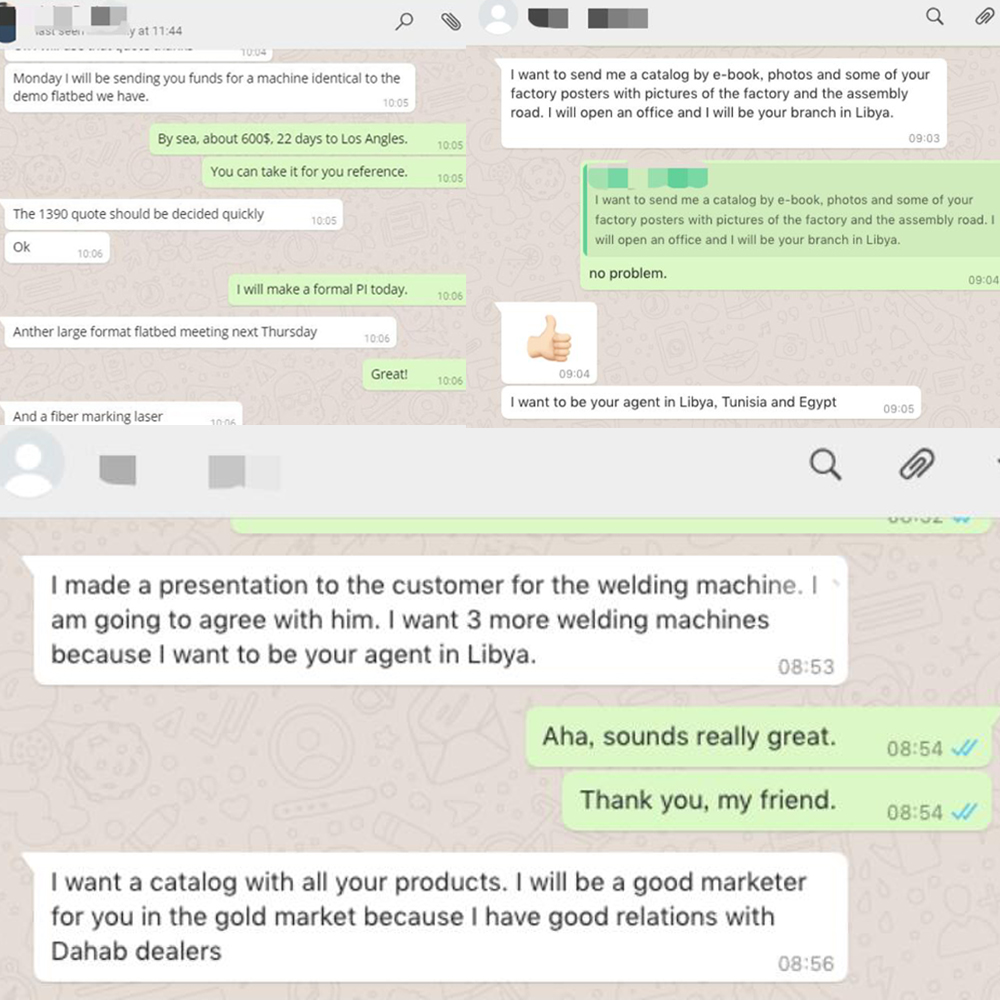

Customers' Feedback

FAQ

Q1: Are you a factory or a trading company ?

A1: We are a trading company based in Hong Kong and have branch of factory in Shenzhen and we provide perfect OEM and after-sale service.

Q2: How was the machine guarantee?

A2: We offer you 12 months guarantee.

Q3: How can I use the machine, if I'm a new buyer?

A3: We will deliver English manual and video with the machine to you. If need our help, please contact us.

Q4: How do you control your quality?

A4: We'll test the machine before the shipment, and let it go through ever check the accuracy. Machines can not be dispatched until finished machine essential complicated test after running at least two days without stopping quality.

Q5: How can I know your machine is designed for my product?

A5: You can send us samples of your product and we test it on machine.

insightlaser

insightlaser