Materials that can be welded are extensive: cold work alloy steel, hot work alloy steel, nickel tool steel, steel alloy, high tenacity aluminum alloy, etc.

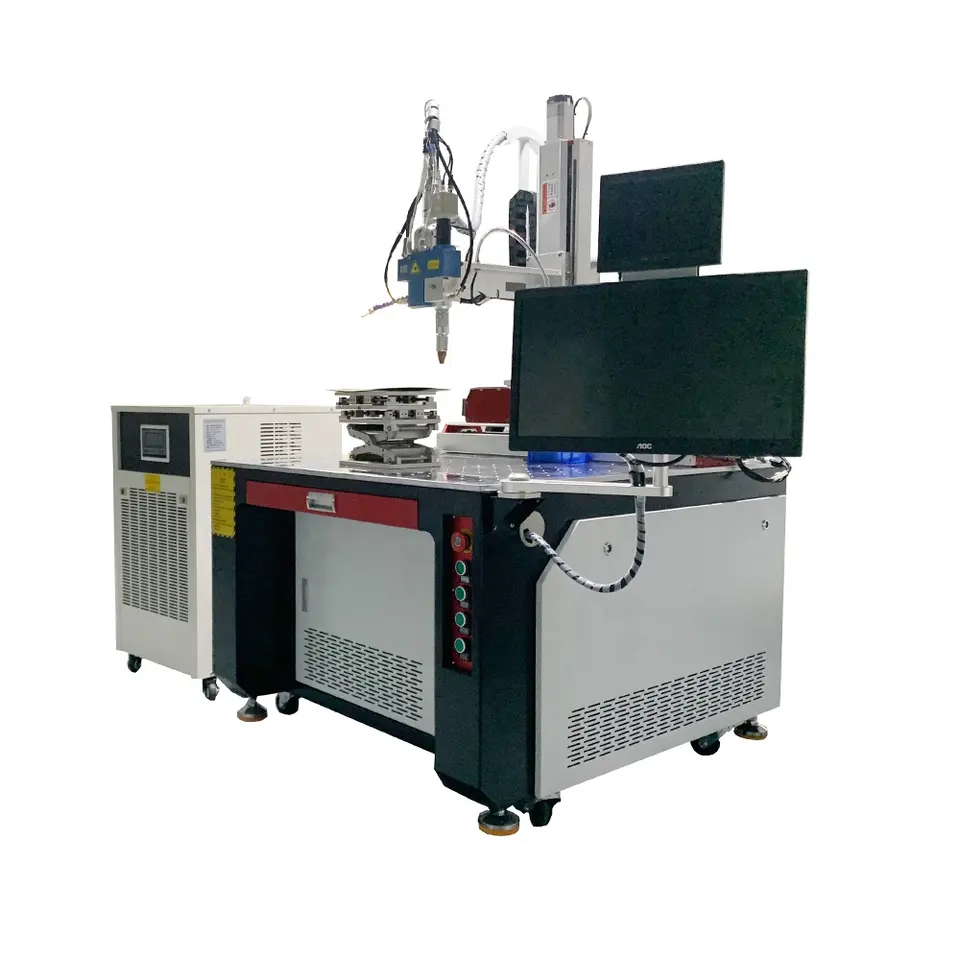

Description

Features:

1. Precisely and fastly weld complex parts, logo, metal words, etc.

2. Perfect welds fully meet the welding requirements of different industries;

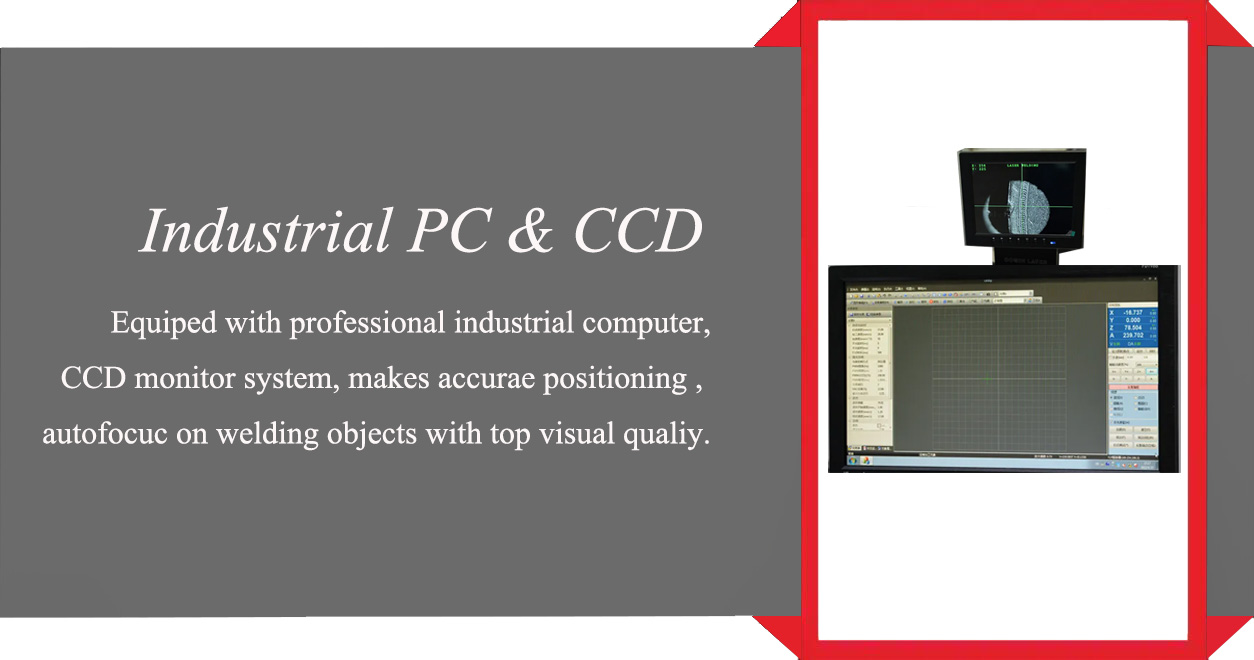

3. CCD camera monitoring system offers real-time display of welding effect;

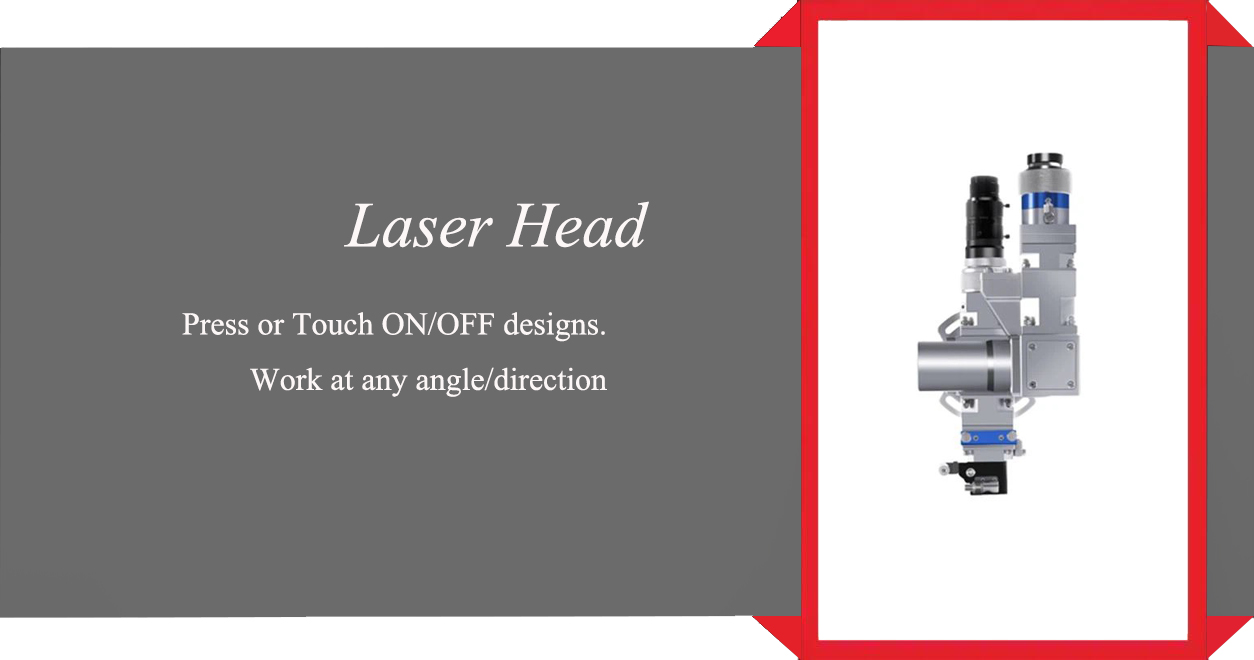

4. 360° rotation welding, large welding range and flexible welding of hard-reach position;

5. Expandable with a handheld welding gun to achieve manual welding;

6. High electro-optic conversion rate and low energy consumption;

7. Suitable for 24h industrial mass production.

Parameters:

| Model | IT-CW1000 | IT-CW1500 | IT-CW2000 | IT-CW3000 |

| Max. Output Power | 1000W | 1500W | 2000W | 3000W |

| Laser Type | Fiber Source | |||

| Wavelength | 1070 nm | |||

| Laser Source | IPG/Raycus/MAX/JPT | |||

| Servo Motor | Panasonic Servo Motor | |||

| Control System | C6L System | |||

| Travel (mm) | X=500, Y=300, Z=500 (Customizable) | |||

| Welding Mode | Circle, Straight Line, Rectangle, Spiral | |||

| Focus Diameter | 0.2mm ~ 1.8mm | |||

| Frequency | 1Hz ~ 5KHz | |||

| Settings Memory | 100 Groups | |||

| Repeatability | ±0.01mm | |||

| Electricity Demands | AC380V, 50Hz/60Hz, 3 Phases | |||

| Positioning System | Red Light | |||

| Output Head Interface | QBH | |||

| Cooling System | Water Cooling | |||

| Auxiliary Gas | Argon or Nitrogen (Purity≥99.9%) | |||

Machine Details:

After-sales Service:

1) Free Pre-Sales Consulting / Free Sample Making

2) Strict Quality Control of Production

3) 3-5 Working Days Quick Delivery for Standard Machine

4) 1 Year Quality Guarantee

5) 24 hours Quick Feedback & After-Sales Service

6) Quick Back-up Parts Available & Technical Assistance

7) Free Online Training Service

8) Special Designing, Customized, OEM Order is accepted

Applicable Industries & Materials:

1. Widely applied in the fields of aeronautical and space, mechanism, electron, communication, dynamic,Chemical, automobile manufacture and other industries.

2. The welding of automobile spare parts, such as hydraulic pressure jib, gasoline cleaner, left gas sensor,Electromagnetic valve, and drive starting stator.

3. The close welding of lithium ion batteries, such as mobile phone batteries and power batteries.

4. In metallurgy industry, such as silicon steel plate welding.

5. The welding of engine and engine lamina in application military industry.

6. The precise spot welding of the electronic components and close welding of relay.

7. In electrical equipments industry, such as silicon steel sheet welding, the rotor of the air-conditioner Drive welding, and creepage protection welding.

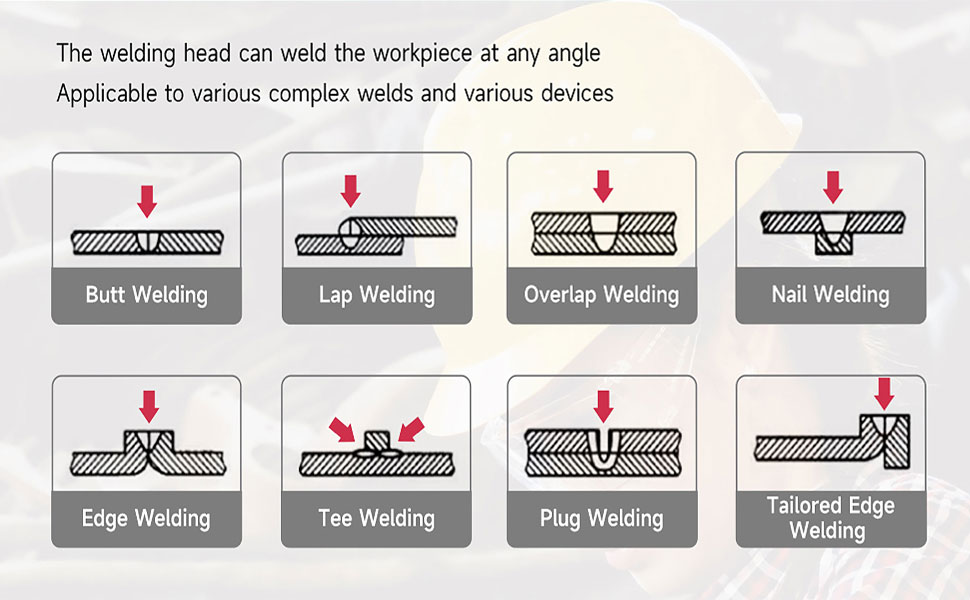

Welding Methods

Certificates:

Samples:

Packages & Delivery:

|

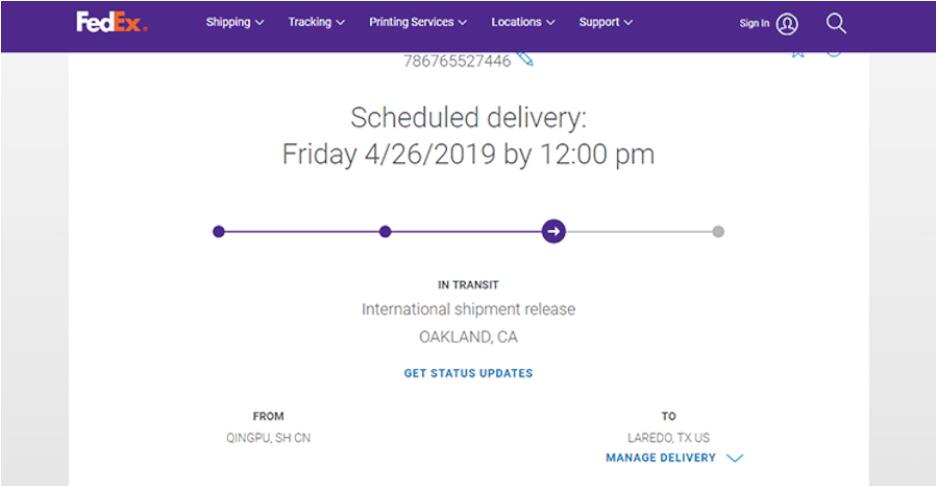

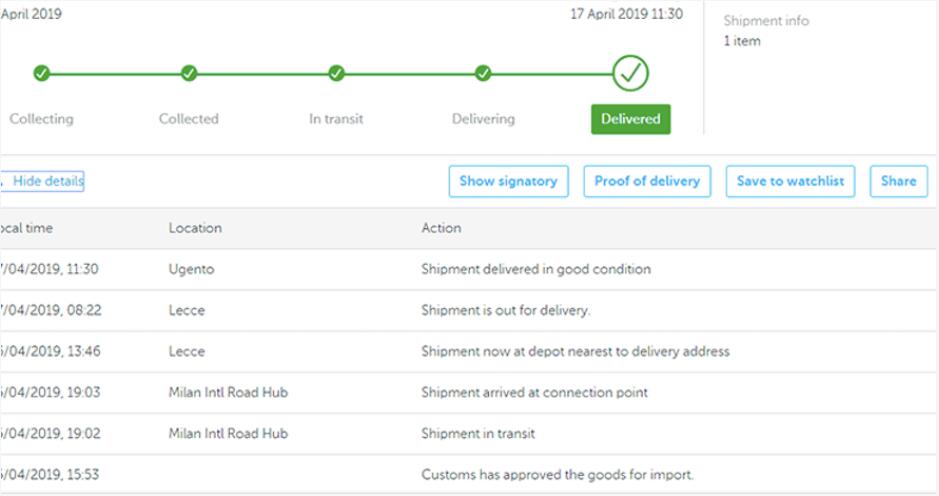

Transport Tracking:

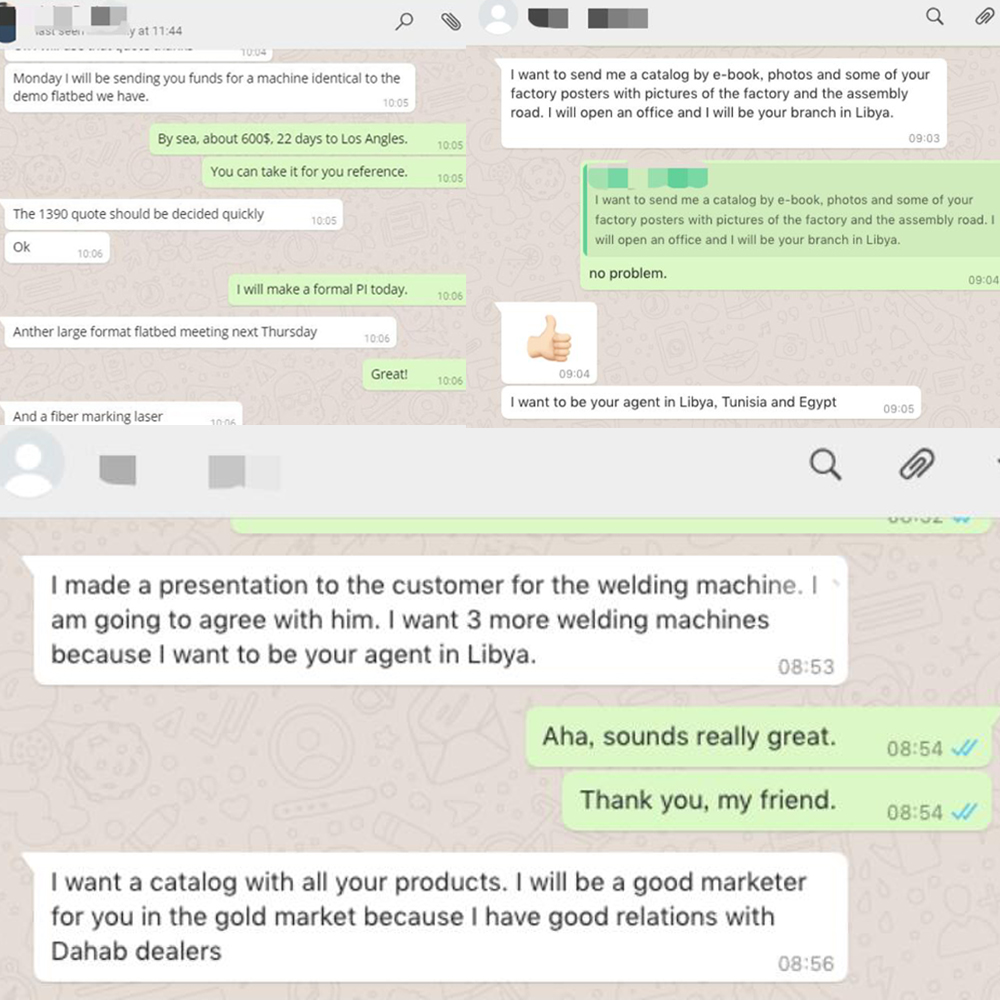

Customers' Feedback:

FAQ

Q1: Are you a factory or a trading company ?

A1: We are a trading company based in Hong Kong and have branch of factory in Shenzhen and we provide perfect OEM and after-sale service.

Q2: How was the machine guarantee?

A2: We offer you 12 months guarantee.

Q3: How can I use the machine, if I'm a new buyer?

A3: We will deliver English manual and video with the machine to you. If need our help, please contact us.

Q4: How do you control your quality?

A4: We'll test the machine before the shipment, and let it go through ever check the accuracy. Machines can not be dispatched until finished machine essential complicated test after running at least two days without stopping quality.

Q5: How can I know your machine is designed for my product?

A5: You can send us samples of your product and we test it on machine.

insightlaser

insightlaser