Suitable for welding stainless steel, carbon steel, alloy steel, spring steel, copper plate, aluminum plate, gold, silver, titanium ect.,

Description

Features:

1. The laser power with 1000W, 1500W, 2000W and 3000W available, laser source with high electro-optical conversion efficiency and long working life.

2. With good laser beam quality, the welding speed is 5 times faster than the speed of traditional welding machine. With better penetration welding, the welding part no need to do further polishing process.

3. With Low energy consumption, less maintenance, high stability and long working life, which can help to save a lot of processing cost for the users.

4. Can be time splitting or energy splitting, suitable for different processing applications, support both continuous welding and spot welding.

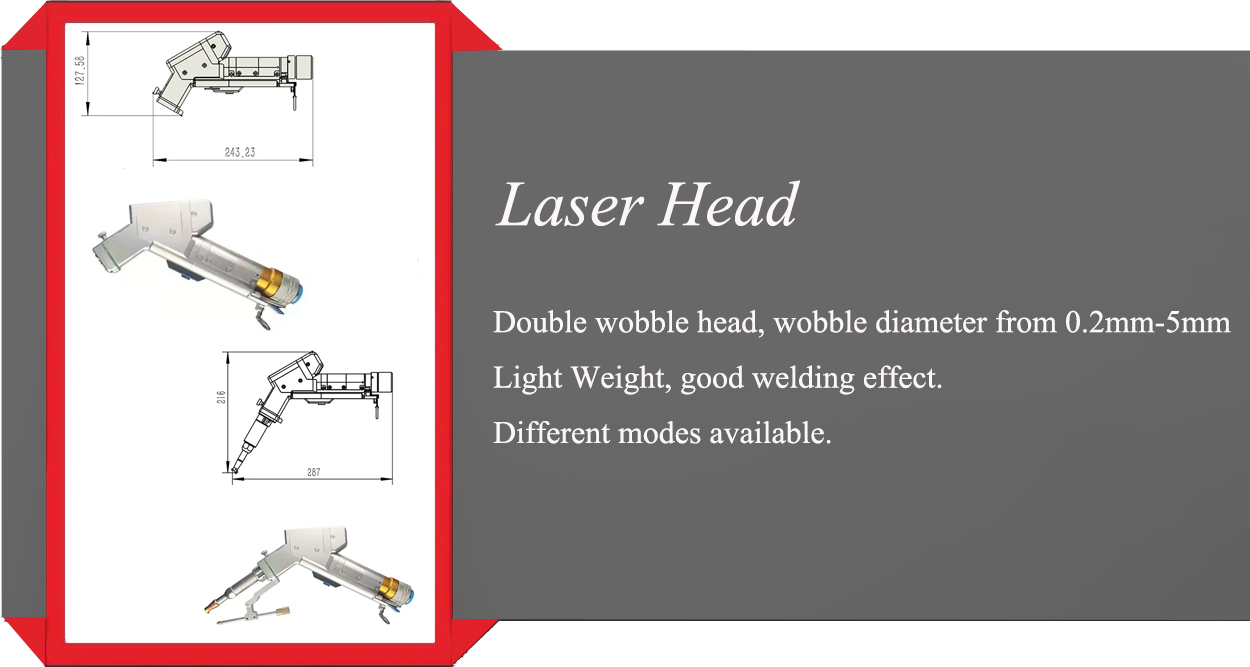

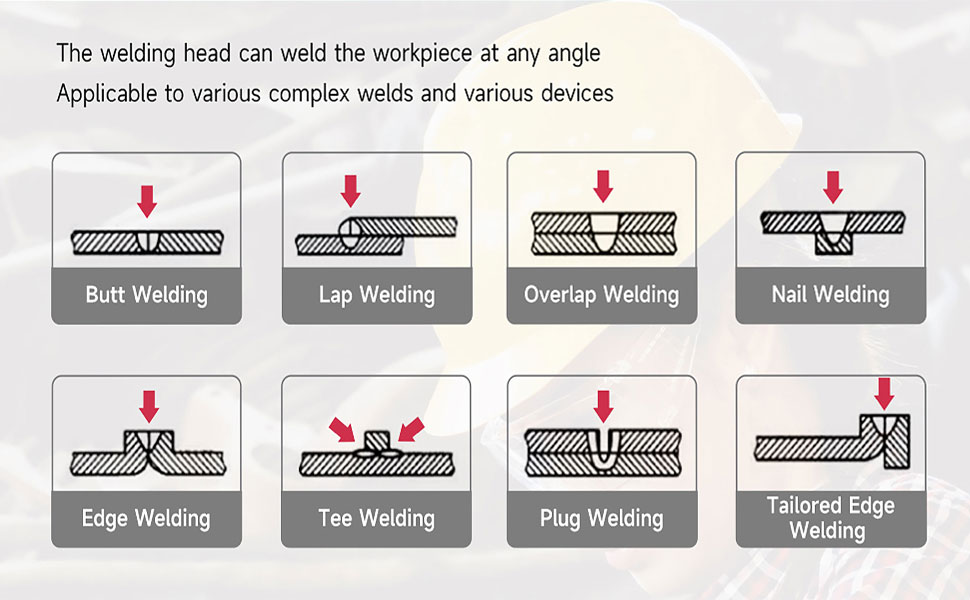

5. The welding gun is with wobble head, and the welding gun is hand-held, flexible and convenient, and the welding distance is longer. Mainly for large workpieces, fixed positions such as inner right angle, outer right angle, flat weld welding, small heat affected area during welding, small deformation, large welding depth and firm welding. It is a relatively flexible new welding process for welding large workpieces at a long distance.

6. This machine combines three functions, can do welding, cutting and cleaning.

Parameters:

| Model | IT-HW1000 | IT-HW1500 | IT-HW2000 | IT-HW3000 |

| Max. Output Power | 1000W | 1500W | 2000W | 3000W |

| Laser Type | Fiber Source | |||

| Wavelength | 1070 nm | |||

| Laser Source | IPG/Raycus/MAX/JPT | |||

| Focus Diameter | 0.1mm ~ 3mm | |||

| Frequency | 1Hz ~ 50Hz | |||

| Repeatability | ±0.01mm | |||

| Electricity Demands | AC220V, 50Hz/60Hz, 1 Phase | AC380V, 50Hz/60Hz, 3 Phases | ||

| Power Consumption | 6KW | 8.5KW | 10KW | 12KW |

| Welding Method | Vertical / Splicing/ Overlap/ Angle | |||

| Welding Mode | CW, PWM and Argon arc and QCW | |||

| Output Head Interface | QBH | |||

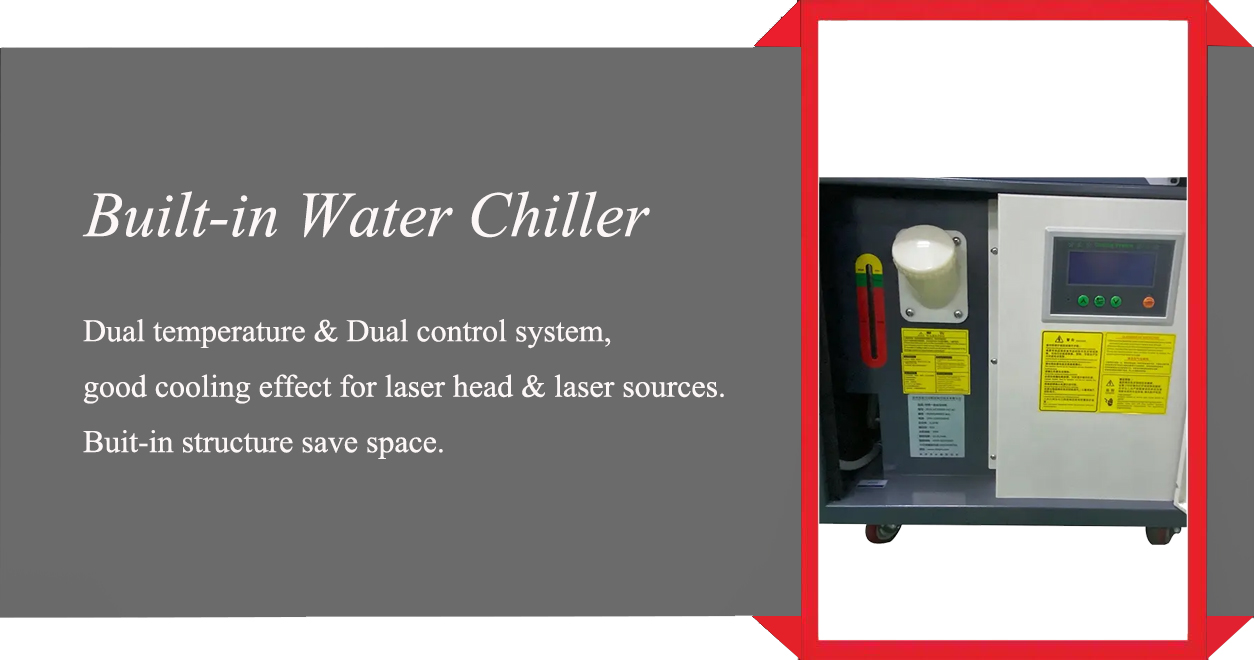

| Cooling System | Water Cooling | |||

| Gas Pressure | 0.1-0.3Mpa or 1-3 bar | |||

| Feeding Wire Diameter | 0.8mm, 1.0mm, 1.2mm ,1.4mm and 1.6mm | |||

| Auxiliary Gas | Argon or Nitrogen (Purity≥99.9%) | |||

Machine Details:

After-sales Service:

1) Free Pre-Sales Consulting / Free Sample Making

2) Strict Quality Control of Production

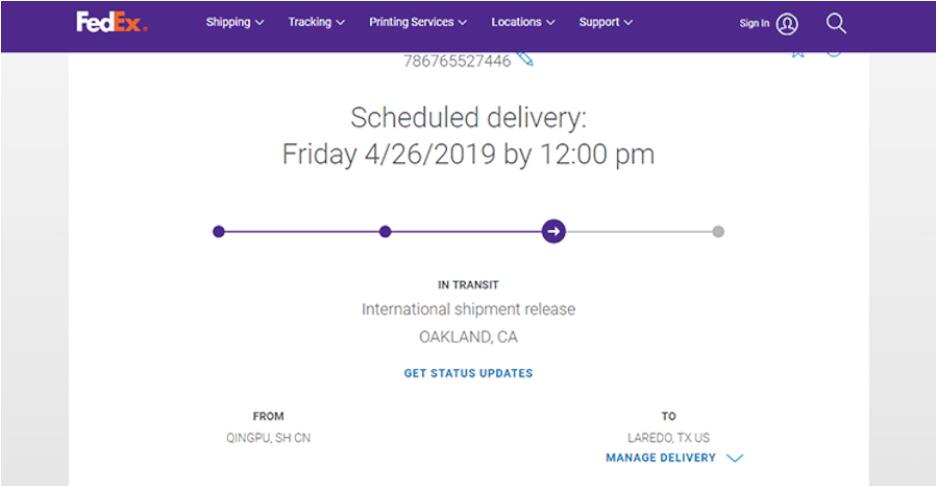

3) 3-5 Working Days Quick Delivery for Standard Machine

4) 1 Year Quality Guarantee

5) 24 hours Quick Feedback & After-Sales Service

6) Quick Back-up Parts Available & Technical Assistance

7) Free Online Training Service

8) Special Designing, Customized, OEM Order is accepted

Applicable Industries & Materials:

Widely used in precision machining of small parts,rings,pendants,bracelets,dentures,mobile phone chargerinterfaces, hardware, watches, sporting goods, golf heads, medical equipment.Titanium alloy jewelry,especially used for holr patching of gold and silver jewelry,spot welding seam pattern,inlaid parts and other welding.

Suitable for welding stainless steel, carbon steel, alloy steel, spring steel, copper plate, aluminum plate, gold, silver, titanium ect.,

Welding Methods

Certificates:

Samples:

Packages & Delivery:

|

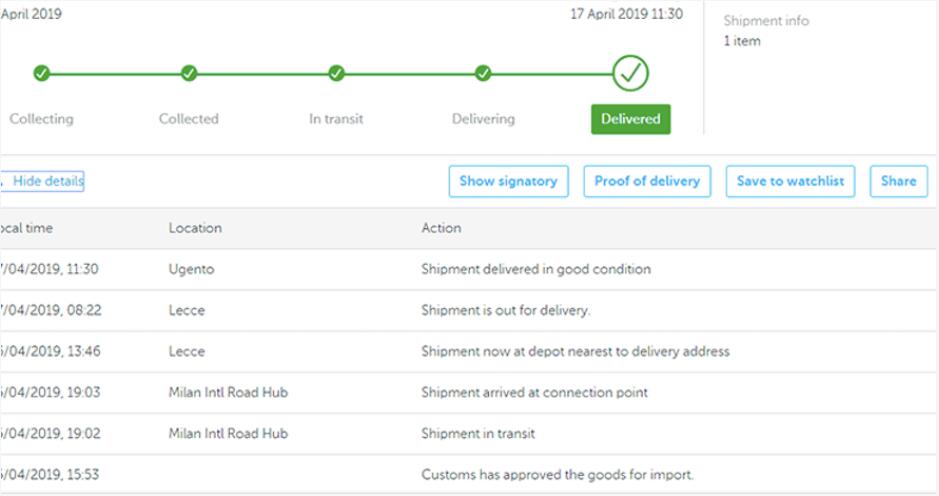

Transport Tracking:

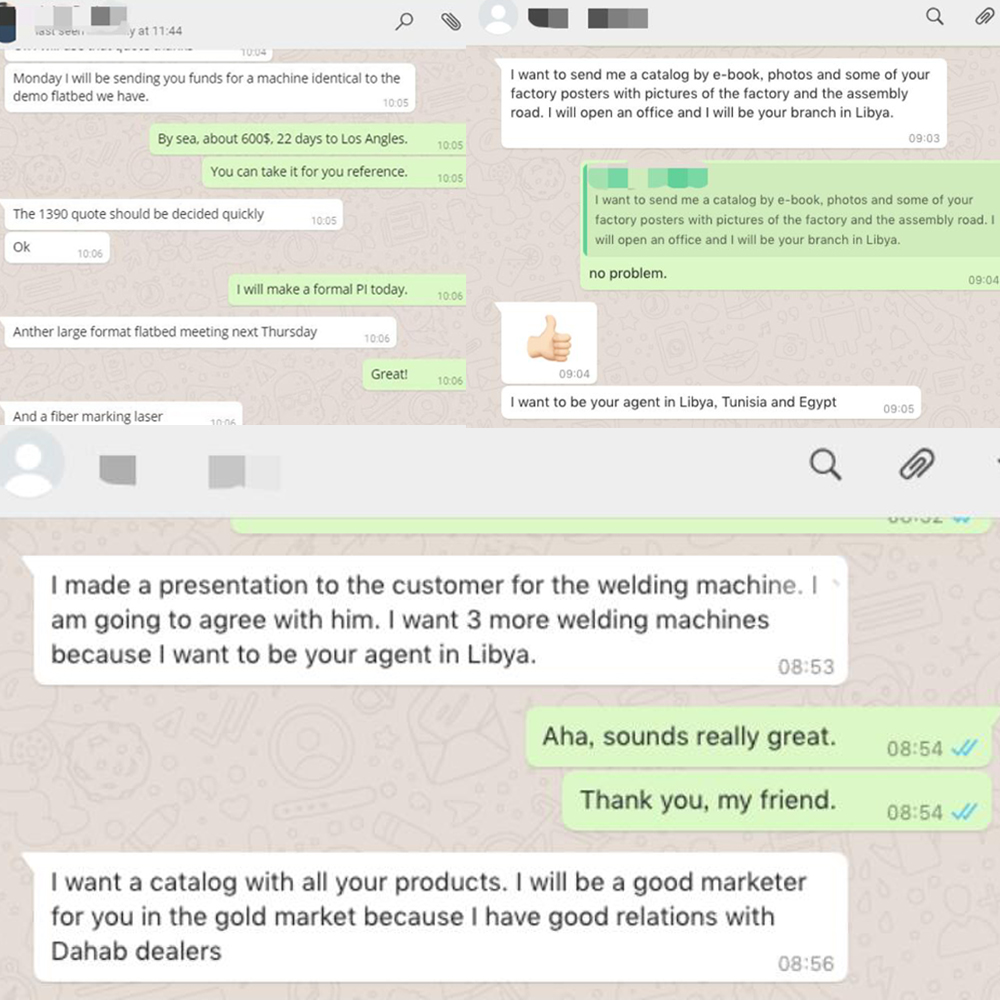

Customers' Feedback:

FAQ

Q1: Are you a factory or a trading company ?

A1: We are a trading company based in Hong Kong and have branch of factory in Shenzhen and we provide perfect OEM and after-sale service.

Q2: How was the machine guarantee?

A2: We offer you 12 months guarantee.

Q3: How can I use the machine, if I'm a new buyer?

A3: We will deliver English manual and video with the machine to you. If need our help, please contact us.

Q4: How do you control your quality?

A4: We'll test the machine before the shipment, and let it go through ever check the accuracy. Machines can not be dispatched until finished machine essential complicated test after running at least two days without stopping quality.

Q5: How can I know your machine is designed for my product?

A5: You can send us samples of your product and we test it on machine.

insightlaser

insightlaser