Specifically for jewelry laser welding of a product, mainly used in gold,bronze,stainless steel and silver ornaments of the hole and spot welding blisters.

Description

Features:

1. Ceramic light collecting cavity, high reflectivity, strong energy, long service life;

2. Special chiller, which meets long-term and high-power welding;

3. Large lifting working table, humanized design, suitable for long-term work without fatigue;

4. Fast speed, high efficiency, large depth, small deformation, small heat-affected zone, high welding quality, no pollution of solder joints, high efficiency and environmental protection;

5. The cross cursor indicates, and the high-speed liquid crystal light valve is used to automatically shield the light.

6. Protective gas output synchronously with the laser ensures that the solder joints are beautiful and will not be oxidized and discolored.

Parameters:

| Model | IT-JW200 |

| Wavelength | 1064 nm |

| Laser Type | Nd: YAG |

| Max. Output Power | 200W |

| Max. Pulse Energy | 100J |

| Pump Source | Single Lamp |

| Spot Size | 0.3mm - 3mm |

| Pulse Width | 0.1ms - 10 ms |

| Pulse Frequency | 1Hz - 20Hz |

| Aiming & Positioning | Microscope or CCD Camera System |

| Application | Welding & Repairing jewelry |

| Host Power Consumption | 7KW |

| Cooling System | Water Cooling |

| Contrl Method | Touch Panel |

| Operation Temerature | 5°C~30°C / 5%-75% humidity |

| Lanague Display | English /Arabic /Thai etc. (Customizable) |

| Packing Size | 125mm*750mm*1400mm (Main Machine) 780mm*600mm*850mm(Water Chiller) |

| Net Weight | 135KG + 50KG |

| Gross Weight | 155KG + 68KG |

Machine Details:

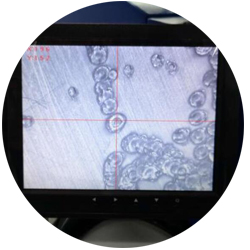

| HD Microscope 10X microscope helpt to achieve preciouse workpiece welding. |

Toch Panel Control System Parameters can be adjusted, multiple groups datas can be saved. |  |

| LED Ring Lamp 360° all-round light source, no ghosting, more conducive to observing the welding part |

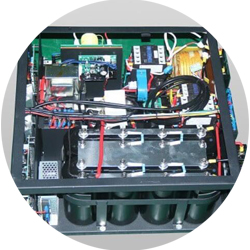

Power Supply Core part of a laser machine, thus a high-performance and stable power supply offers you a good working experience. |  |

| Emergency Stop Button Protect your safety by stopping the machine immediately without causing any further harm. |

External Water Chiller Real-time monitor the water temperature, to maintain stable work for 24 hours. |  |

| 7 inch HD CCD Screen (Optional Parts) CCD display to make observation more convenient during welding. |

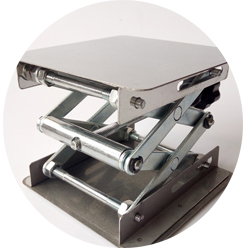

Lifting Table(Optional Parts)

For comfortable lifiting when welding |  |

After-sales Service:

1) Free Pre-Sales Consulting / Free Sample Making

2) Strict Quality Control of Production

3) 3-5 Working Days Quick Delivery for Standard Machine

4) 1 Year Quality Guarantee

5) 24 hours Quick Feedback & After-Sales Service

6) Quick Back-up Parts Available & Technical Assistance

7) Free Online Training Service

8) Special Designing, Customized, OEM Order is accepted

Applicable Materials:

Widely used in precision machining of small parts,rings,pendants,bracelets,dentures,mobile phone chargerinterfaces, hardware, watches, sporting goods, golf heads, medical equipment.Titanium alloy jewelry,especially used for holr patching of gold and silver jewelry,spot welding seam pattern,inlaid parts and other welding.

Certificates:

Samples:

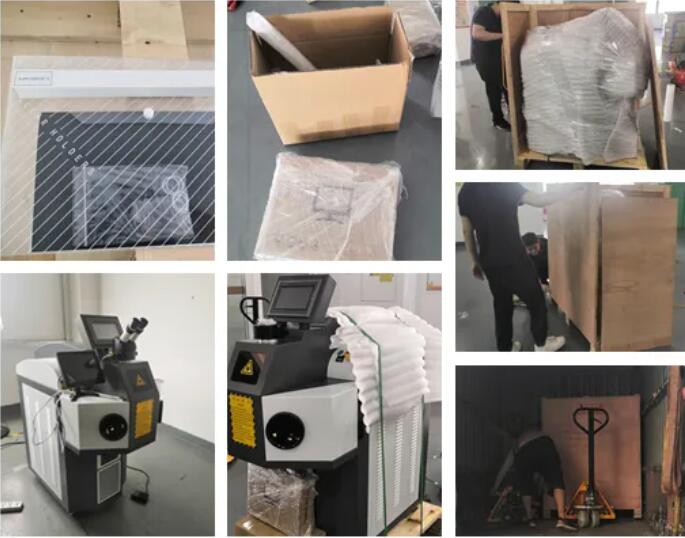

Packages & Delivery:

| Machine delivery time: 3-5 working days. The machine will packed with two wooden package. Machine main part: Length: 125cm, Width:75cm, Height: 140cm; / 155KG Water chiller part: Length: 780cm, Width: 60cm, Height: 85cm; / 68KG |

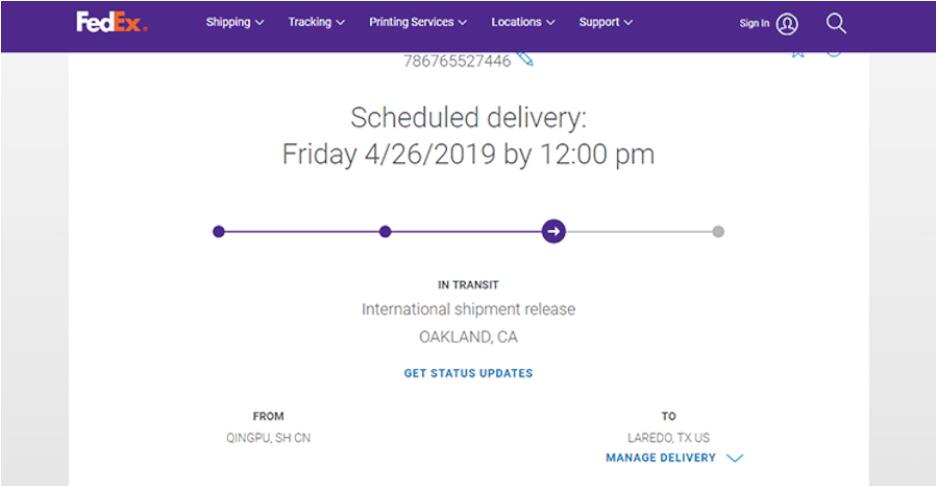

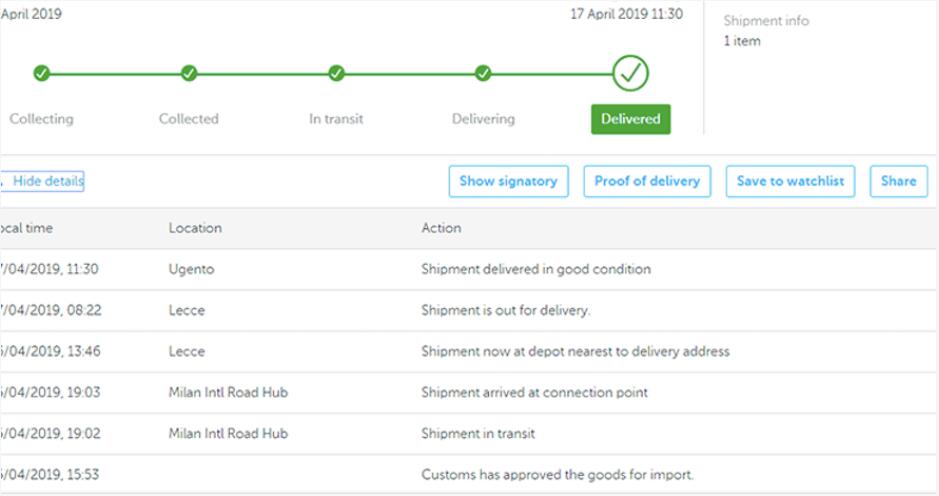

Transport Tracking:

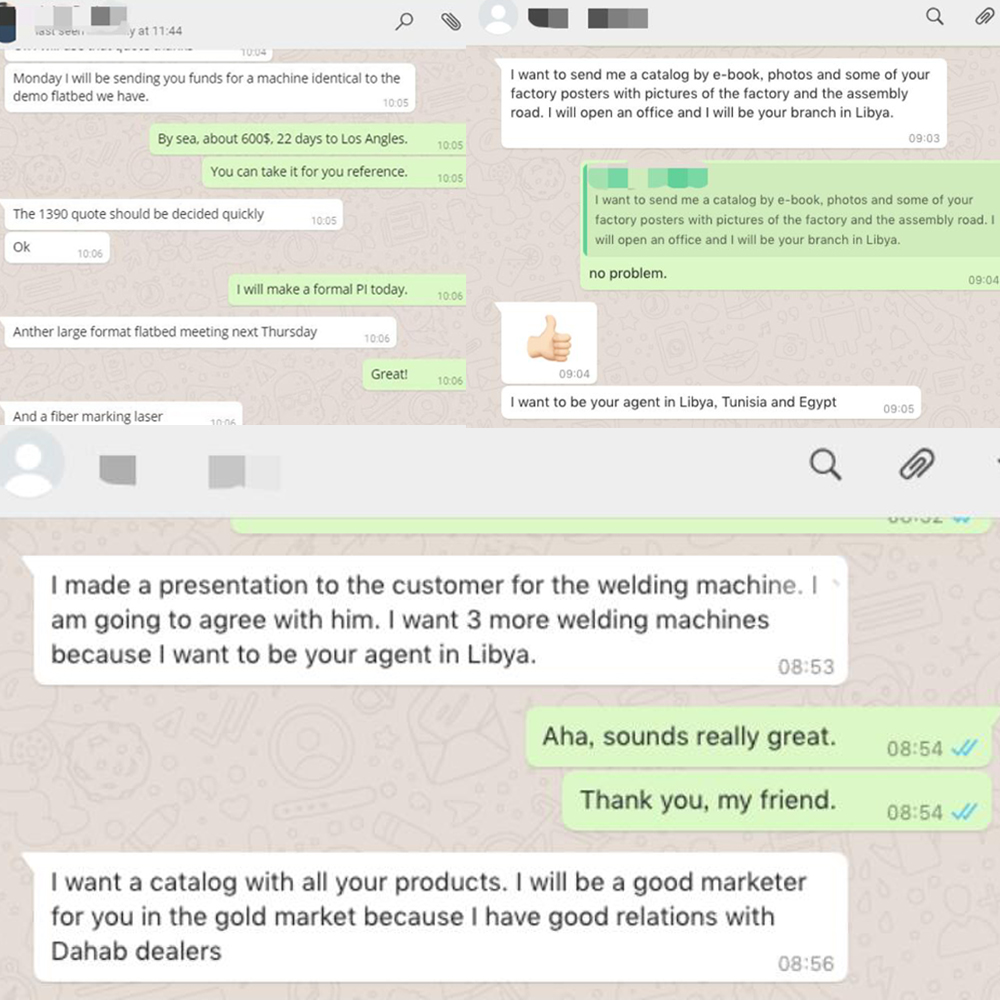

Customers' Feedback:

FAQ

Q1: Are you a factory or a trading company ?

A1: We are a trading company based in Hong Kong and have branch of factory in Shenzhen and we provide perfect OEM and after-sale service.

Q2: How was the machine guarantee?

A2: We offer you 12 months guarantee.

Q3: How can I use the machine, if I'm a new buyer?

A3: We will deliver English manual and video with the machine to you. If need our help, please contact us.

Q4: How do you control your quality?

A4: We'll test the machine before the shipment, and let it go through ever check the accuracy. Machines can not be dispatched until finished machine essential complicated test after running at least two days without stopping quality.

Q5: How can I know your machine is designed for my product?

A5: You can send us samples of your product and we test it on machine.

insightlaser

insightlaser