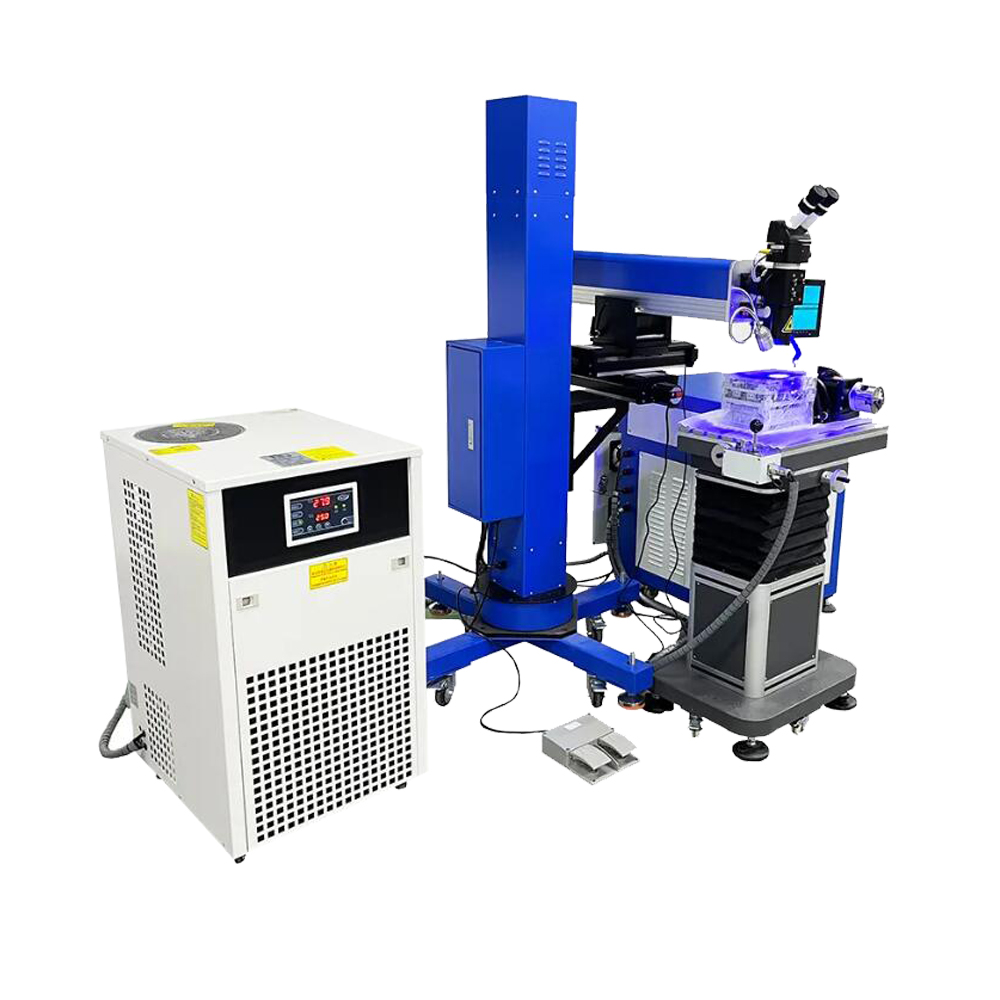

Suitable for large, medium and small molds of welding, aluminium welding. It is widely used in chassis, automobiles, ships, auto parts, bearings, construction machinery and other mold manufacturing and molding industry.

Description

Introduction:

This machine is suitable for large, medium and small molds of welding, aluminium welding. It is widely used in chassis, automobiles, ships, auto parts, bearings, construction machinery and other mold manufacturing and molding industry. This types of welding machine can welding a variety of mold steel, stainless steel, cymbals steel, precious metals and hard materials, aluminium welding. Precision injection molding, die-casting, mold repair and accessories, precision stamping parts of the welding, lost wax castings, aluminum castings, stainless steel products sand hole.

Features:

High pulse energy.

Using the anti-erosive, high temperature resistant and ceramic reflector cavity. The working life of cavity up to 8-10 years. Xenon Lamp with 3 millions of times life-span.

High efficiency YAG crystal to ensure the best beam quality and energy.

Adopting the most advanced auto light-shielding system in the world to prevent the laser from hurting the eyes.

Small range of heat, the work piece will not be deformed.

It can weld in narrow position, welding deeper, and would not hurt the edge.

Parameters is easy to set via machine's touch screen.

No need to modify the mould, it can save a lot of material, labor, time and cost.

Stable laser power supply to ensure the system able to operate in 24 hours.

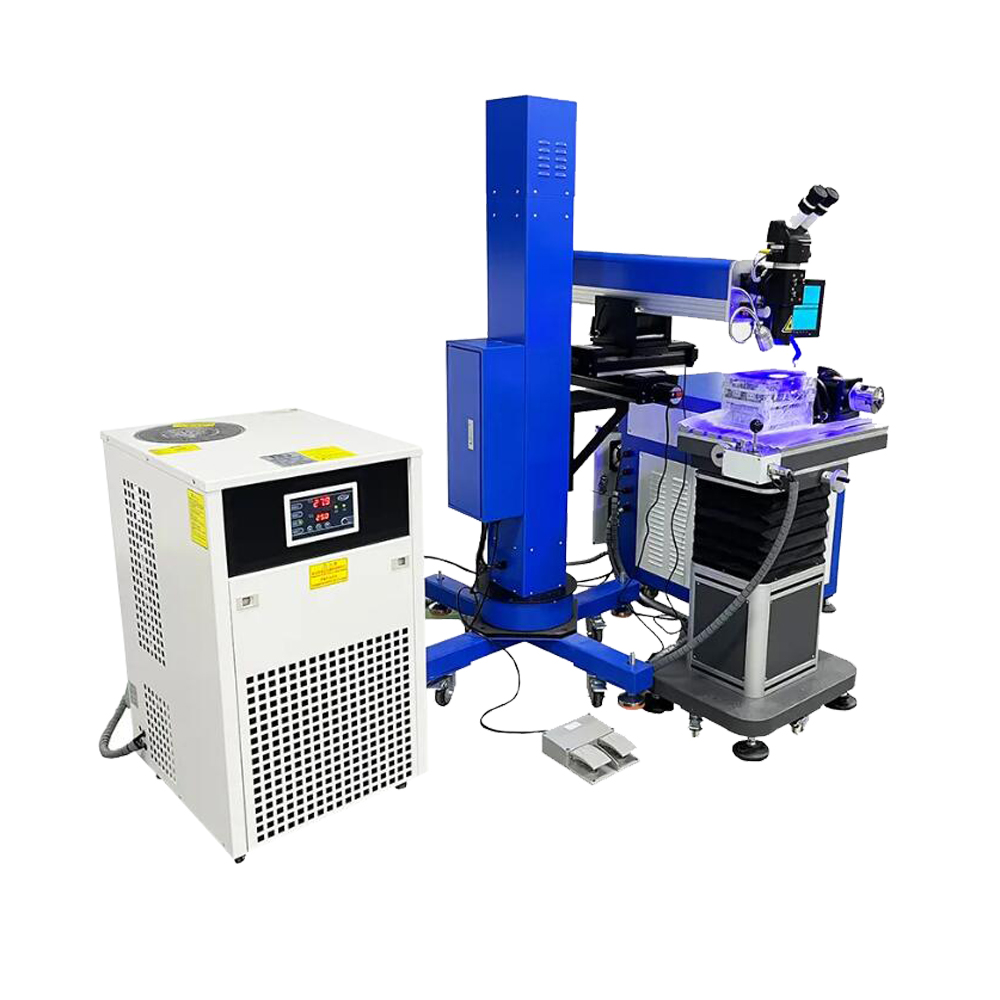

The laser head and the entire optical path can rotate 360 degrees. With cantilever type design, it is very convenient to weld big and heavy sized mold.

Both manual welding and automatic mass production can be provided by us.

Parameters:

| Model | IT-MW200 | IT-MW300 | IT-MW400 | IT-MW500 |

| MAX. Output Power | 200 Watts | 300 Watts | 400 Watts | 500 Watts |

| Laser Type | Nd3+: YAG | |||

| Wavelength | 1064 nm | |||

| Max Single Pulse Energy | 100J | 110J | 120J | 140J |

| Xenon Lamp | Single Xenon Lamp | Single Xenon Lamp | Dual Xenon Lamps | Dual Xenon Lamps |

| Laser Cavity | Ceramic Cavity | Ceramic Cavity | Metal Cavity | Metal Cavity |

| MAX. Pulse Frequency | ≤30Hz | ≤30Hz | ≤40Hz | ≤50Hz |

| Peak Power | 8KW | 12KW | 18KW | 24KW |

| Pulse Width | 0.1-6ms | 0.1-6ms | 0.1-8ms | 0.1-10ms |

| Welding Depth | 0.1mm-1.5mm | 0.1mm-2mm | 0.1mm-2.5mm | 0.1mm-3mm |

| Focal Diameter | 0.3-3.0mm | |||

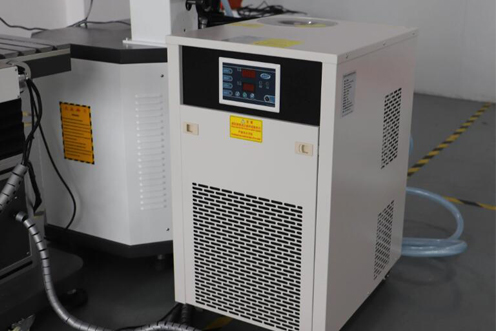

| Cooling system | External water cooling | |||

| Vision system | 10X Stereo microscope + CCD Camera Display (optional) | |||

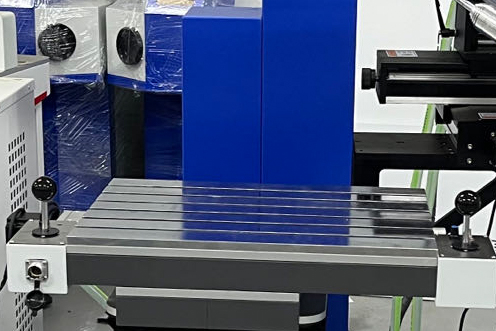

| Worktable | X :200mm,Y :100mm,Z :200mm; Loading ability:≤200kg | |||

| Work Range | X:400mm,Y: 200mm,Z:700mm | |||

| Water Chiller | 1P | 1.5P | Small 3P | Big 3P |

| Power Supply | AC220V/50Hz-60Hz | AC380V/50Hz-60Hz | ||

Details of Machine:

| Touch Screen Only four parameters need to set: Current, pulse, frequency and light (Spot size). With Chinese, English, Korea, Russian languages available for screen. On the monitor screen you can check the xenon lamp lighting times in real-time. |

High Quality Microscope With standard 10X high quality microscope. We can also customize the microscope with 12.5X, 16X, etc. It help you to observe the material welding position and welding situation very clearly. |  |

| Welding Head The welding head with 360 degrees rotation, it can meet the requirements to weld different welding angles. |

Foot pedal The left side black foot pedal is to control laser emit. The right side big foot pedal is to control the cantilever "UP" and "DOWN" |

|

| Motorized Working Table & Remote Controller Electric moving with 8 directions. X axis moving stroke: 250mm; Y axis moving stroke:150mm; Z axis moving stroke:200mm; The left controller controls the working table X and Y axis moving. The right controller controls the cantilever X and Y axis moving. |

Water Chiller It with dual temperature and dual control system, which with good cooling effect and support long hours continuous working. |  |

| Cantilever type (Manual Model) Z axis with motorized moving, X and Y axis with manual moving. X axis stroke: 700mm Y axis stroke: 680mm Z axis stroke: 750mm |

Cantilever type (Motorized Model) X, Y and Z axes all with motorized moving. With forward & backward moving system X axis stroke: 200mm Y axis stroke: 200mm Z axis stroke: 750mm |  |

| Cantilever type (Motorized Model) X, Y and Z axes all with motorized moving. With forward & backward moving system X axis stroke: 200mm Y axis stroke: 200mm Z axis stroke: 750mm |

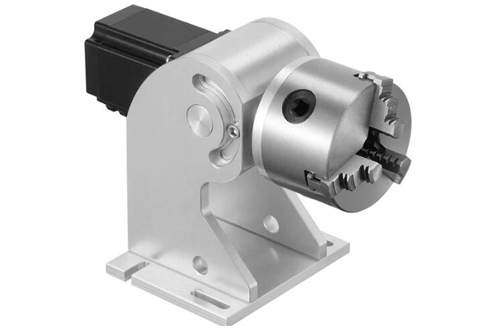

| Rotary Axis ( Optional Parts)If you need to weld round & irregular products, a rotary axis can help you to fix the products for better welding. We have different specifications available. For different size, you can feel free to ask me. |

Colorful CCD (Optional Parts)If the machine continuously works for long a long time and you observe via the microscope for a long time, your eyes will feel tired, at this moment a CCD is very necessary. You can observe the welding status via CCD instead of microscope. | |

| Magnetic Ball ( Optional Parts)It's used to fix the small metal parts for convenient welding. Different specifications available. |

Dust Extractor ( Optional Parts)It's used to collect the dust & smoke while the machine is welding the materials. |

Applicable Industry:

1. Widely applied in the fields of aeronautical and space, mechanism, electron, communication, dynamic,Chemical, automobile manufacture and other industries.

2. The welding of automobile spare parts, such as hydraulic pressure jib, gasoline cleaner, left gas sensor,Electromagnetic valve, and drive starting stator.

3. The close welding of lithium ion batteries, such as mobile phone batteries and power batteries.

4. In metallurgy industry, such as silicon steel plate welding.

5. The welding of engine and engine lamina in application military industry.

6. The precise spot welding of the electronic components and close welding of relay.

7. In electrical equipments industry, such as silicon steel sheet welding, the rotor of the air-conditioner Drive welding, and creep-age protection welding.

After-sales Service:

1) Free Pre-Sales Consulting / Free Sample Making

2) Strict Quality Control of Production

3) 5-7 Working Days Quick Delivery for Standard Machine

4) 1 Year Quality Guarantee

5) 24 hours Quick Feedback & After-Sales Service

6) Quick Back-up Parts Available & Technical Assistance

7) Free Online Training Service

8) Special Designing, Customized, OEM Order is accepted

Applicable Materials:

Materials that can be welded are extensive: cold work alloy steel, hot work alloy steel, nickel tool steel, steel alloy, high tenacity aluminum alloy, etc. Other metals like gold, silver, brass, aluminum-magnesium alloy, titanium, and platinum are also applicable.

Certificates:

Samples:

Packages & Delivery:

| Machine delivery time: 7 working days. The machine will packed with two wooden package. Machine main part+ cantilever part : Length: 151cm; Width: 150cm; Height: 190cm Water chiller part: Length: 92cm; Width:61cm; Height:107cm Total gross weight: 549 KGS Total measurement: 4.904 CBM |

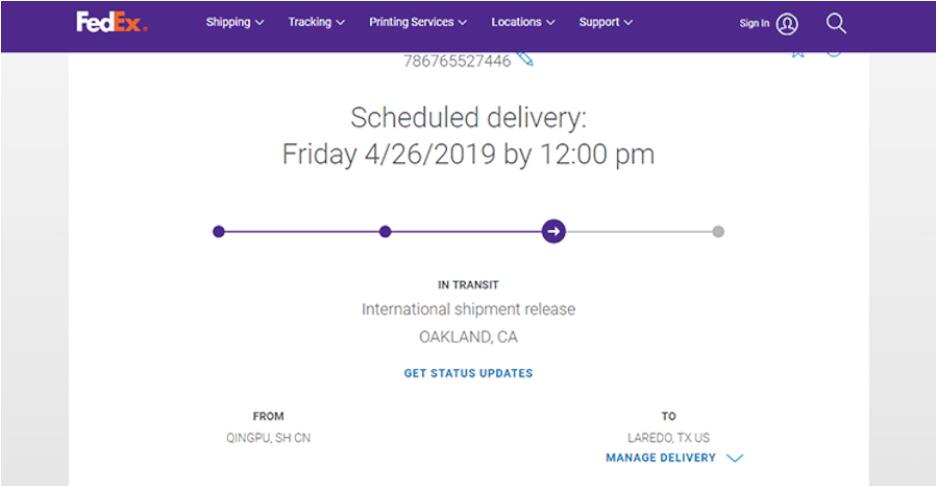

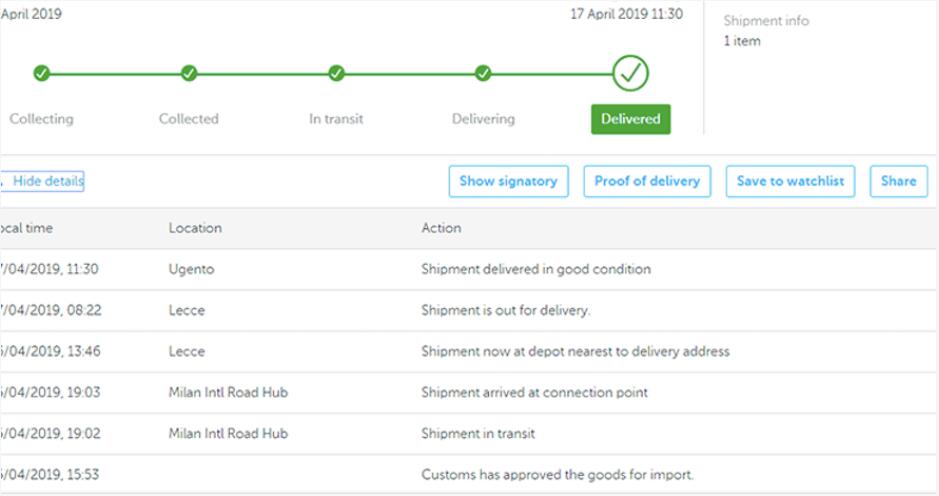

Transport Tracking:

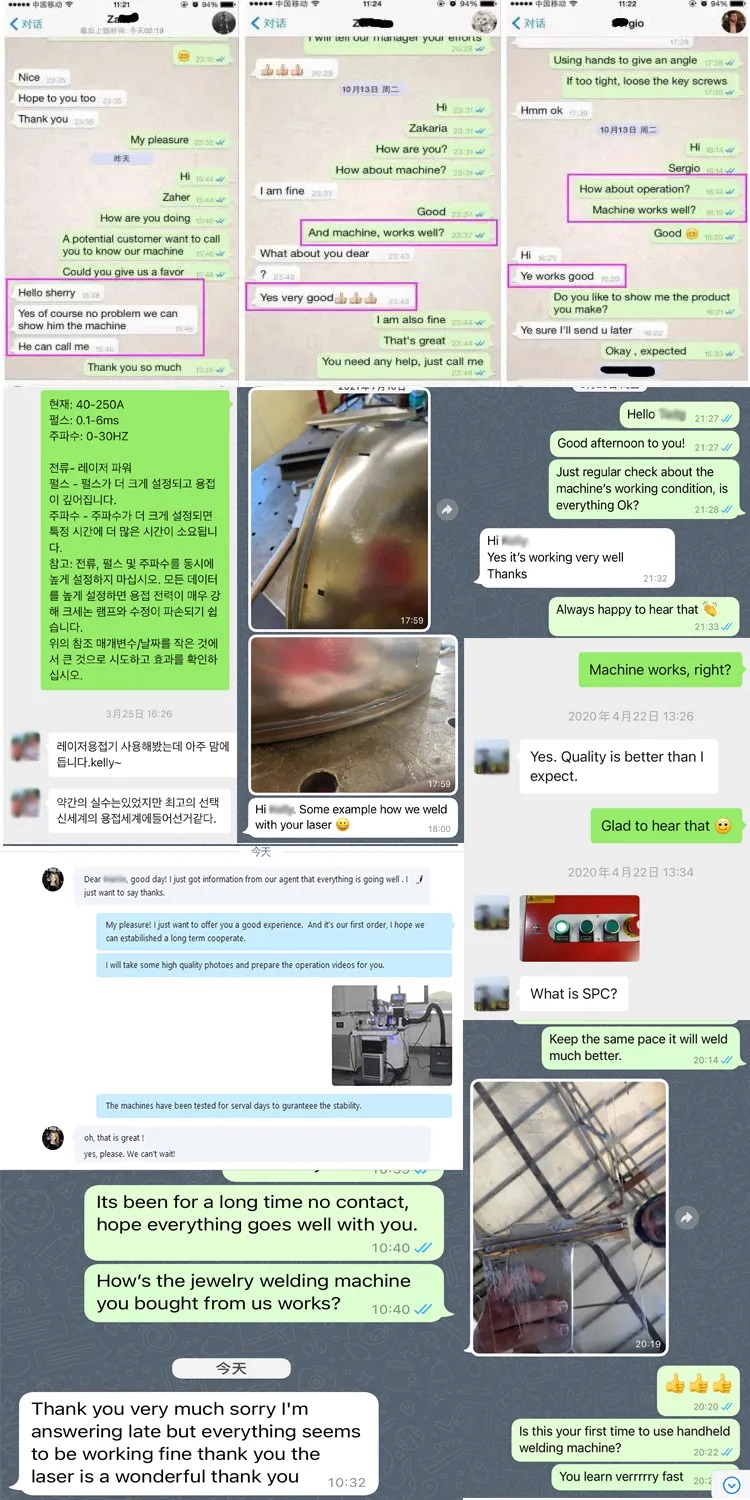

Customers' Feedback:

FAQ

Q1: Are you a factory or a trading company ?

A1: We are a trading company based in Hong Kong and have branch of factory in Shenzhen and we provide perfect OEM and after-sale service.

Q2: How was the machine guarantee?

A2: We offer you 12 months guarantee.

Q3: How can I use the machine, if I'm a new buyer?

A3: We will deliver English manual and video with the machine to you. If need our help, please contact us.

Q4: How do you control your quality?

A4: We'll test the machine before the shipment, and let it go through ever check the accuracy. Machines can not be dispatched until finished machine essential complicated test after running at least two days without stopping quality.

Q5: How can I know your machine is designed for my product?

A5: You can send us samples of your product and we test it on machine.

insightlaser

insightlaser